Auger Filler VFFS Pro

Hygienic & Safe Design

International Standards

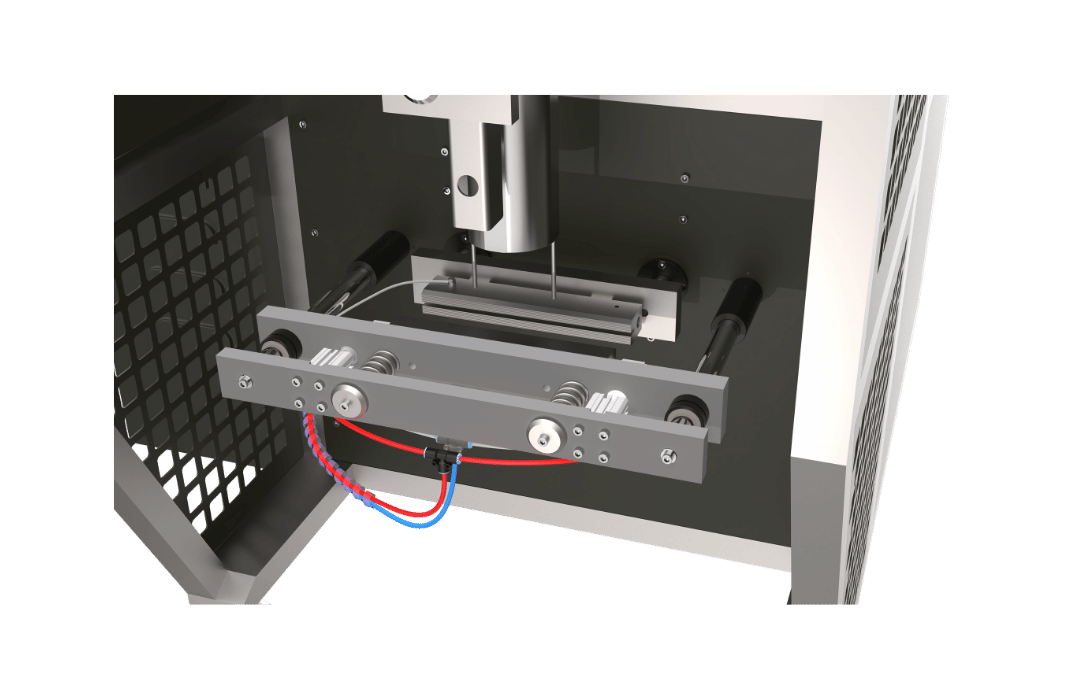

Pneumatic Operations

Secured Sealing

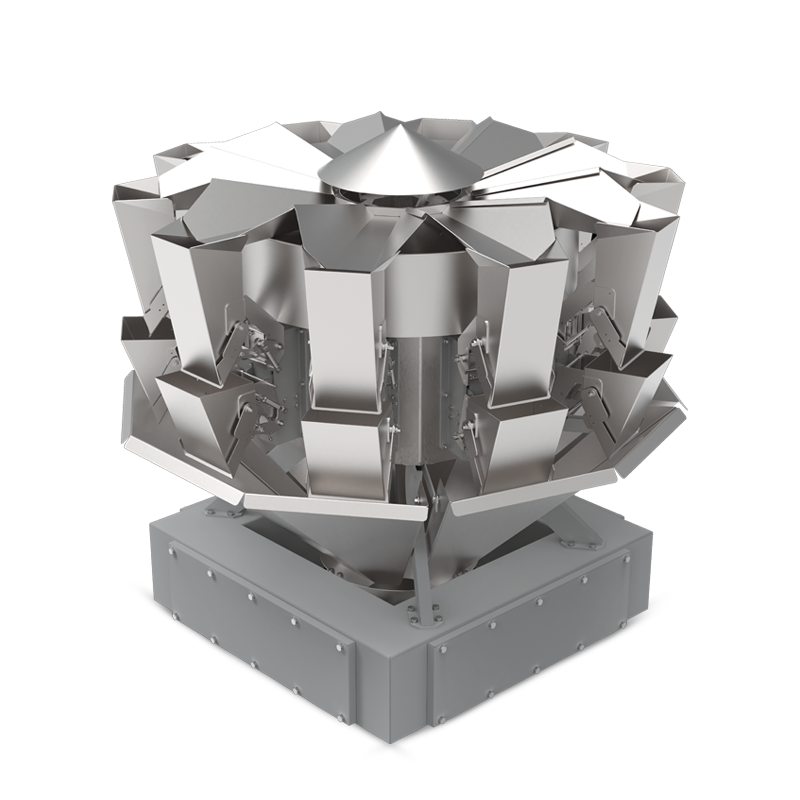

Consistent Weighing

Capability to pack more Weight

Types of packages

Products that can be packed

Technical Specification

Production Capacity |

||

|---|---|---|

| Cycle per Min. |

20 to 25 Pouch per Minute (Depend on Product and Weight) |

|

| Pouch Volume Capacity | 10 Grams to 1000 Grams (Depend on Product) | |

| Error in Weight | ± 2 to ± 3 Grams | |

| Product Type | Food, Pharmaceuticals, Powders, Chemicals, Cosmetics, Spices, Coffee, Etc. | |

Machine Specification |

||

| Hopper Capacity |

50 Ltr. (Depending on Product and Desired Volume) |

|

|

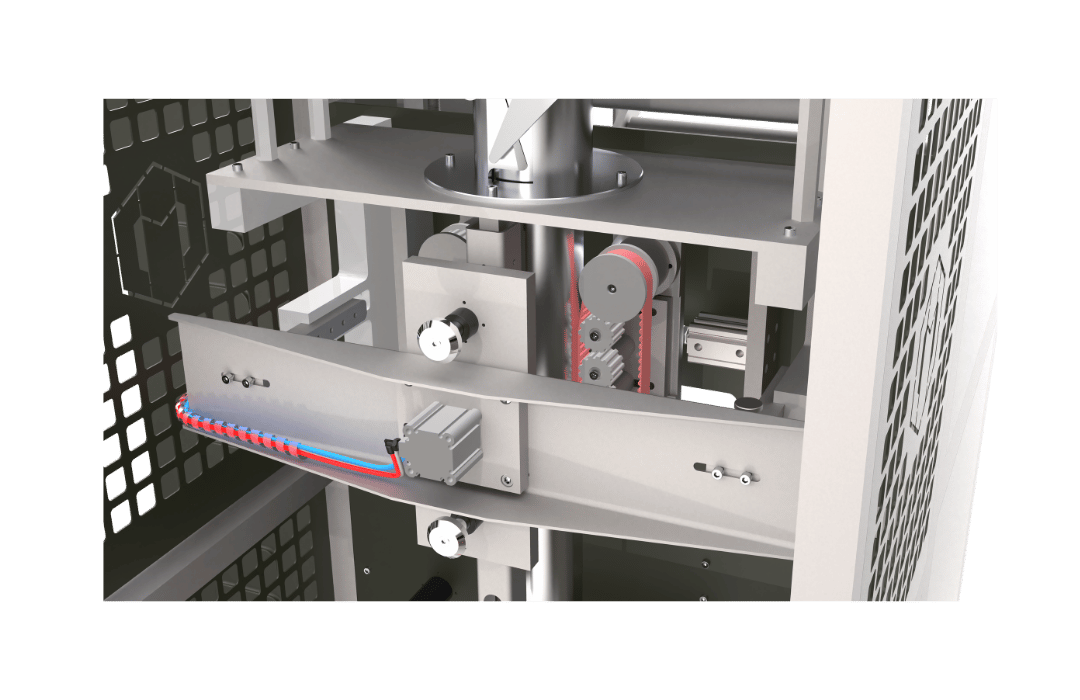

Auger Screw Type |

Helical or Spiral Auger for Smooth and Controlled Product Dispensing |

|

|

Filling System |

Auger Screw for Powdery or Granular Product Filling (Adjustable for Product Flow and Density) |

|

| Sealing Type |

Center Seal / Side Seal |

|

| Packing Material |

Laminated Heat Sealable Film |

|

| Humidity |

20% to 80% RH |

|

|

Automation Level |

Fully Automated Filling, Sealing, and Pouch Handling |

|

|

Batch Coding |

35 mm x 35 mm (Printing Area) |

|

Electrical Specification |

||

|

Control & Command System |

PLC & HMI 7" (Touch Screen) (Fuji) |

|

|

Power Supply |

3 KW (1-Phase) |

|

|

Heater |

Ceramic Heater (Rod Type) |

|

|

Sealing Temperature Range |

100°C to 220°C (Adjustable for Different Film Types) |

|

|

Data Logging |

Production Monitoring, Error Tracking, and Pouch Count Logging |

|

| Sensor | Photoelectric Sensors For Pouch Detection, Filling Level Control, and Sealing | |

Pneumatic Specification |

||

| Air Pressure Required | 6 to 7 Bar | |

| Pneumatic Cylinder | SMC | |

| Batch Type Coding | Pneumatic Batch Coding | |

Machine Structure |

||

| Machine Construction | M.S. Duly Powder Coated | |

|

Contact Parts |

Food-Grade Stainless Steel for Easy Cleaning and Durability |

|

|

Weighing Platform |

Stainless Steel, Vibration-Resistant Design for Accurate Measurements |

|

|

Number of Screw |

1 Nos. |

|

|

Weighing Method |

Screw Filling |

|

|

Weighing Precision |

Adjustable Depending on the Product’s Required Weight Tolerance |

|

|

Machine Length |

~ 1100 mm |

|

|

Machine Width |

~ 1740 mm |

|

| Machine Hight | ~ 3300 mm | |

| Machine Weight | ~ 650 Kg. | |

Optional Features |

||

|

Printer |

High-Quality, Durable Printing of Variable Batch Coding and Barcodes on Flexible Packaging Printing | |

|

Vacuum |

Removes Air From The Packaging, To Enhance Product Preservation and Prevent Spoilage | |

Required Accessories |

||

| Air Compressor | 3 H.P. (3-Phase) | |

| Ventilation | Required For Cooling and Exhaust, Particularly for High-Speed or Continuous Operations | |

| Stabilizer | 3 KVA |

.png)

.png)

(6).png)

(1).png)