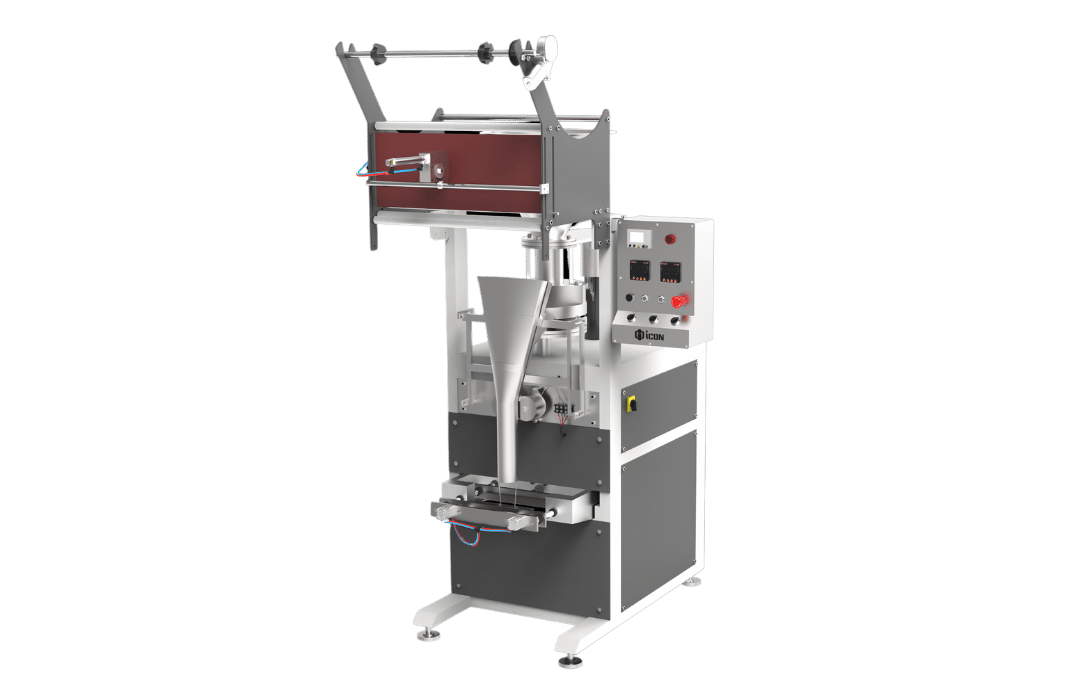

Cup Filler VFFS Prime

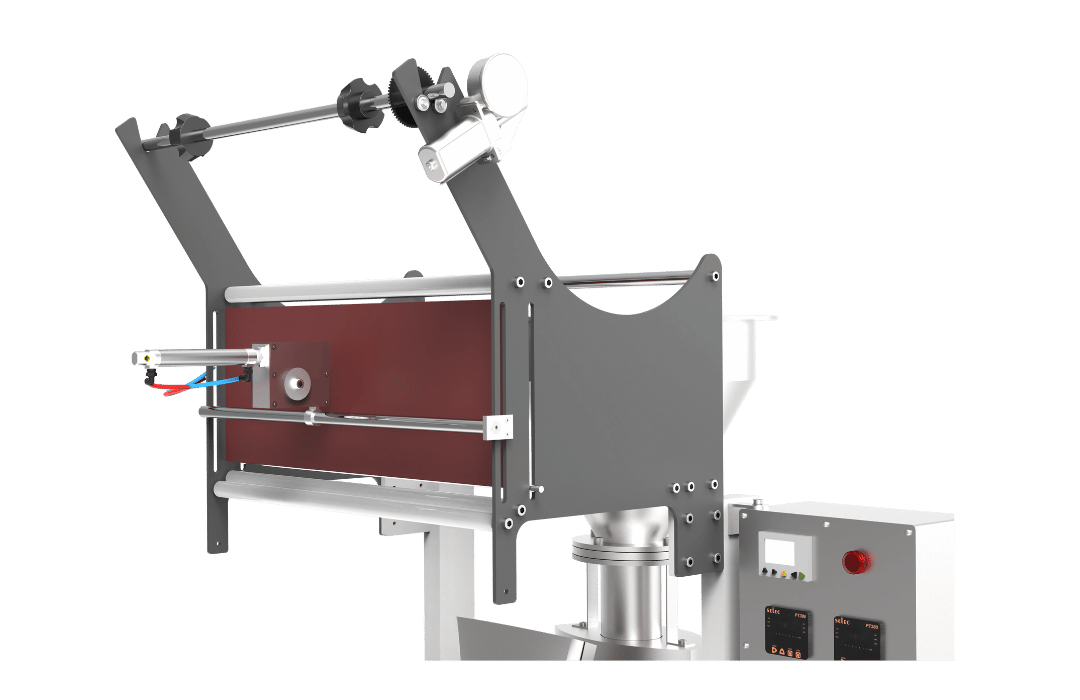

Hygienic & Safe Design

International Standards

Pneumatic Operations

Limited Weight Variants

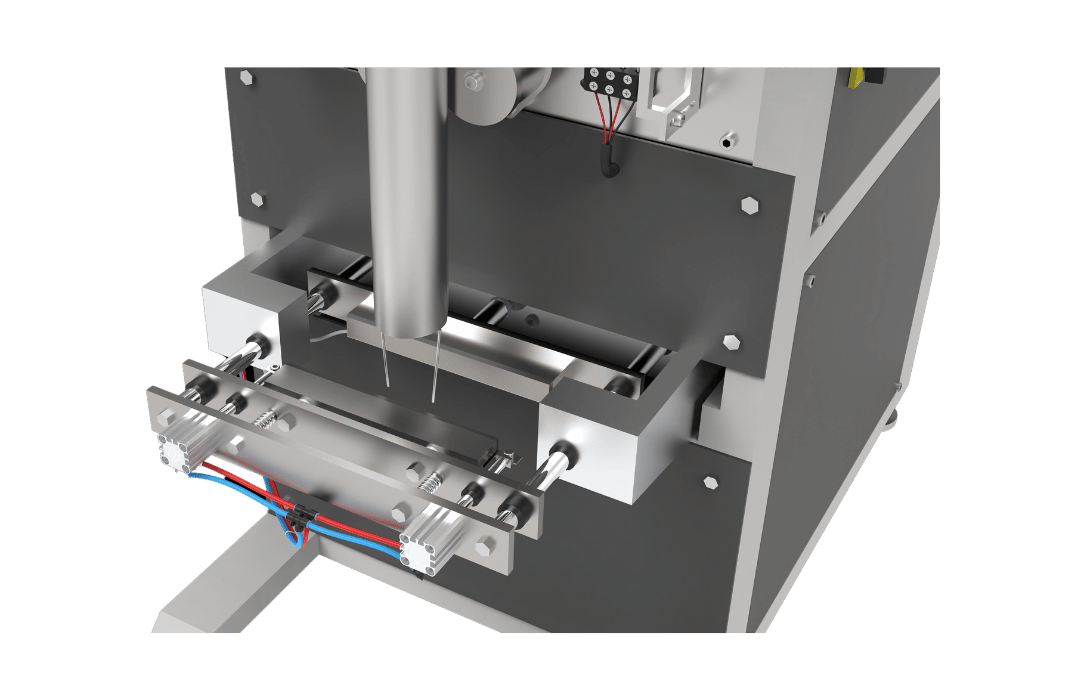

Secured Sealing

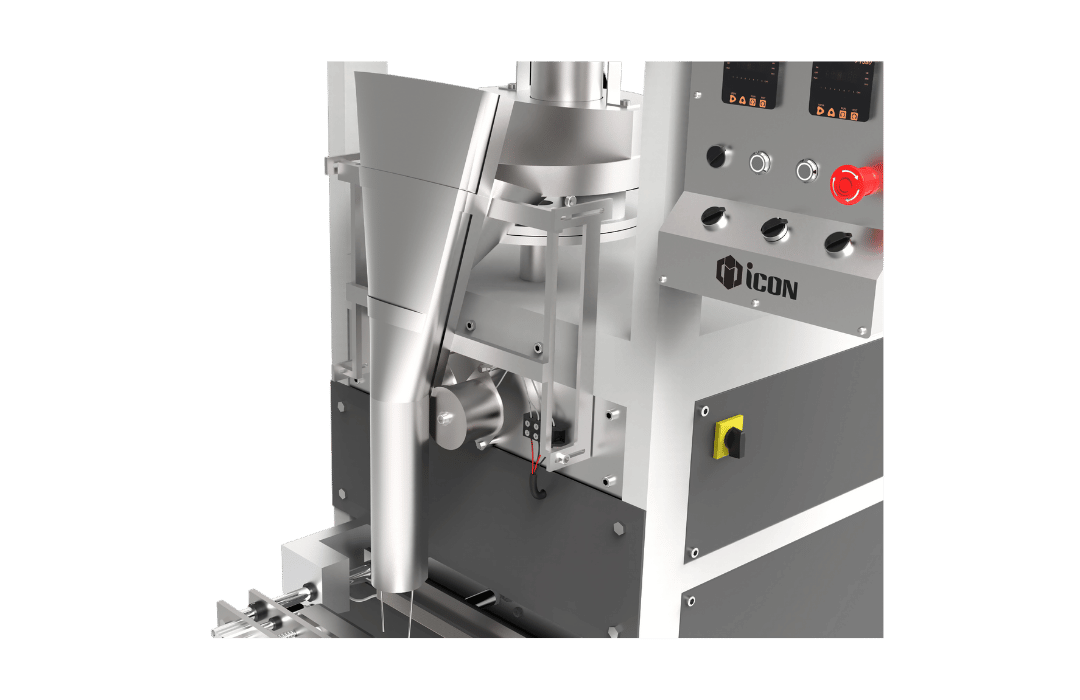

Consistent Filling

Types of packages

Gas Flushing

Center Seal

Side Seal

Volumatric Weighing

Fill

Seal

Products that can be packed

Free-Flow Powder

Spices

Namkeen & Farsan

Convenience Foods

Plastic Granules

Household Products

Pet Food

Technical Specification

Production Capacity |

||

|---|---|---|

| Cycle per Min. | 20 to 25 Pouch / Min. (Depend on Product and Load) | |

| Pouch Volume Capacity | 250 to 500 gm (Depend on Product) | |

| Error in Weight | ±0.5 to ± 2 Gram (Depends on Product and Load) | |

| Product Type | Granules, Powder, Solid Products, Snacks, Nuts, Candies, Etc. | |

Machine Specification |

||

| Hopper Capacity |

30 Ltr. (Depending on Product and Desired Volume) |

|

|

Filling System |

CUP Filling |

|

| Sealing Type |

Center Seal / Side Seal |

|

| Packing Material |

Laminated Heat Sealable Film |

|

| Automation Level |

Fully Automated Filling, Sealing, and Pouch Handling |

|

|

Batch Coding |

35 mm x 35 mm (Printing Area) |

|

Electrical Specification |

||

|

Control & Command System |

PLC & HMI 7" (Touch Screen) (Fuji Make) |

|

|

Power Supply |

4 KW (1 Phase) |

|

|

Heater |

Ceramic Heater (Rod Type) |

|

|

Sealing Temperature Range |

100° C to 220° C (Adjustable for Different Film Types) |

|

| Data Logging | Production Monitoring, Error Tracking, and Pouch Count Logging | |

|

Sensor |

Photoelectric Sensors for Pouch Detection, Filling Level Control, and Sealing |

|

Pneumatic Specification |

||

| Air Pressure | 6 to 7 Bar | |

| Pneumatic Cylinder | SMC | |

| Batch Coding | Pneumatic | |

Machine Structure |

||

|

Machine Construction |

M.S. Duly Powder Coated |

|

|

Contact Parts |

Food-Grade Stainless Steel for Easy Cleaning and Durability |

|

|

Number of CUPS |

4 to 6 Nos. |

|

|

Machine Length |

~ 944 mm |

|

| Machine Width | ~ 1537 mm | |

|

Machine Hight |

~ 2034 mm |

|

|

Machine Weight |

~ 550 kg. |

|

Optional Features |

||

| Printer | High-Quality, Durable Printing of Variable Batch Coding and Barcodes on Flexible Packaging Printing | |

| Nitrogen Flushing | Remove Oxygen From The Packaging, Preserving Product Freshness and Extending Shelf Life | |

| Vacuum | Removes Air From The Packaging, To Enhance Product Preservation and Prevent Spoilage | |

Required Accessories |

||

|

Air Compressor |

3 H.P. | |

|

Stabilizer |

3 KVA |

.png)

.png)

.png)

.png)

(11).png)

(16).png)

(5).png)