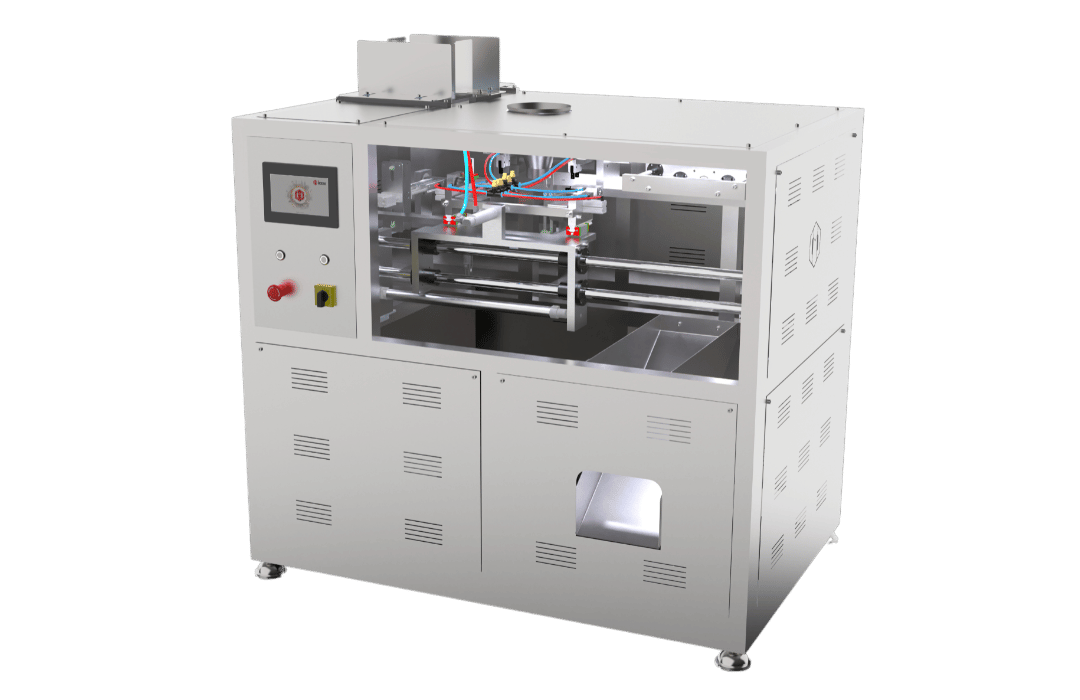

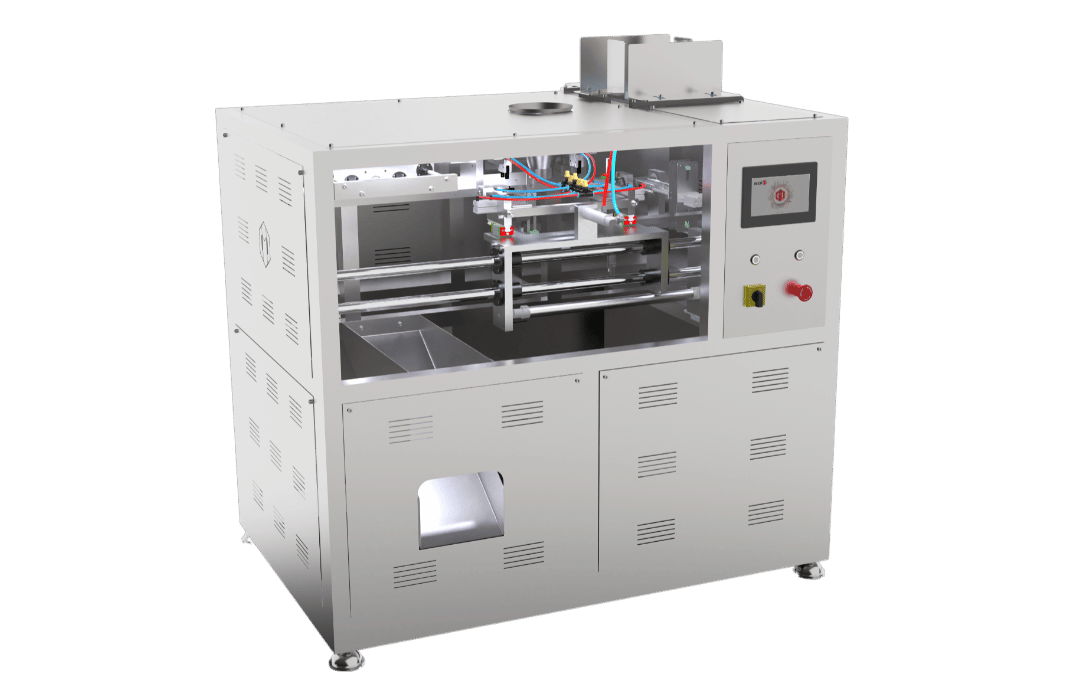

Linear PFS Machine

Hygienic & Safe Design

Consistent Quality

International Standards

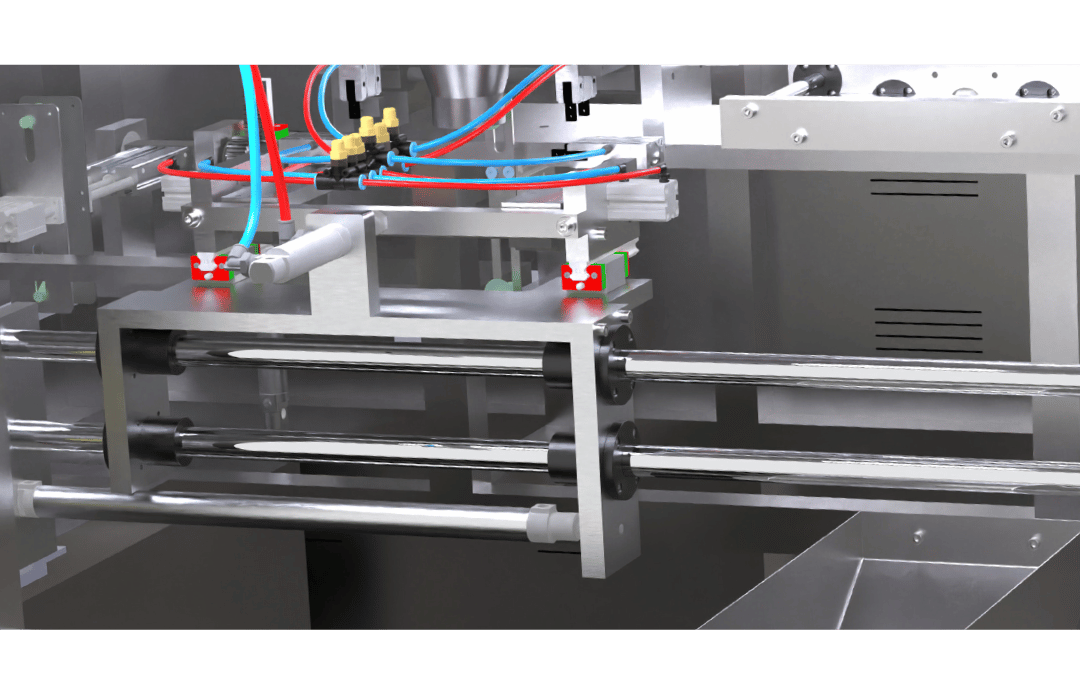

Pneumatic Operations

Secured Sealing

High Production Output

Types of packages

3 Side Seal Pouch

Gadget

Zipper Pouch

Standy Pouch

Pick

Fill

Seal

Products that can be packed

Dates

Free-Flow Powder

Dry Fruits

Namkeen & Farsan

Convenience Foods

Confectionery

Pulses & Produce

Agriculture

Household Products

Pet Food

Technical Specification

Production Capacity |

||

|---|---|---|

| Cycle per Min. |

30 to 50 Pouches / Minute (Depends on Pouch Size, Filling Material) |

|

| Pouch Volume Capacity |

50 Gm to 1500 Gm (Depends on Product and Pouch Size) |

|

| Pouch Type | Flat, Stand-Up, Pre-Formed Pouches or Gusseted Pouches | |

| Pouch Sizes | Adjustable to Pre Decided Limits | |

| Product Type | Dry Powders, Granules, Liquids, Pastes, or Small Solid Items | |

| Error In Weight |

±1% to ±2% (Depending on Filling System) |

|

|

|

||

Machine Specification |

||

| Model |

IPFS Pro |

|

| Hooper Volume |

1.6 L (Can be Customized) |

|

| Drive Actuator |

Pneumatic |

|

| Filling System | Volumetric, Auger, Pump, or Gravimetric Filling (Depending on The Product) | |

Electrical Specification |

||

|

Control System |

PLC & 7 Inch Touch Screen (Fuji) |

|

|

Data Logging |

Production Monitoring, Error Tracking, and Pouch Count Logging |

|

|

Sensor |

Photoelectric Sensors for Pouch Detection, Filling Level Control, and Sealing | |

| Power Supply | 220 V (1-Phase) | |

Pneumatic Specification |

||

|

Air Required |

6 to 7 Bar | |

|

Pneumatic Cylinder |

SMC |

|

|

Batch Coding |

Pneumatic | |

Machine Structure |

||

| Machine Construction | M.S. Duly Powder Coated | |

| Contact Parts | Stainless Steel | |

| Machine Length | ~ 1285 mm | |

|

Machine Width |

~ 870 mm |

|

|

Machine Hight |

~ 1300 mm | |

|

Machine Weight |

~ 800 kg - 1500 kg (Varies by Model) | |

Optional Features |

||

| Printer | High-Quality, Durable Printing of Variable Batch Coding and Barcodes on Flexible Packaging Printing | |

| Nitrogen Flushing | Remove Oxygen From The Packaging, Preserving Product Freshness and Extending Shelf Life | |

| Vacuum | Removes Air From The Packaging, to Enhance Product Preservation and Prevent Spoilage | |

Required Accessories |

||

| Air Compressor | 5 H.P. | |

| Stabilizer | 3 KVA |

.png)

.png)

.png)

.png)