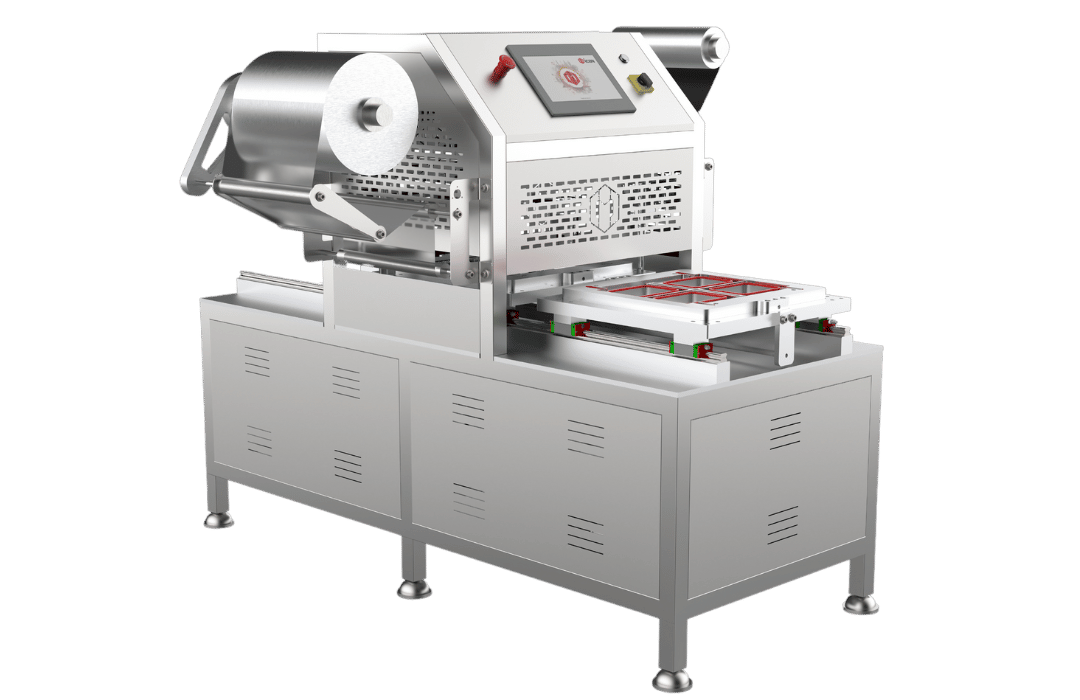

Shuttle Type Tray Sealer (MAP)

Hygienic & Safe Design

Consistent Quality

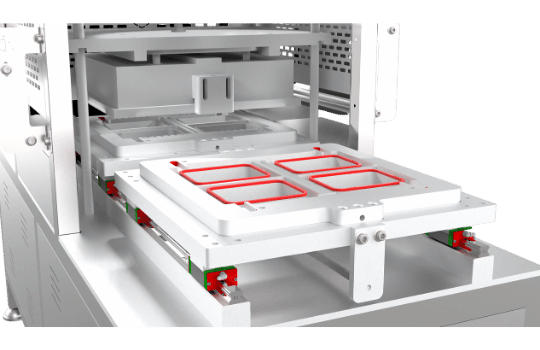

Secured Sealing

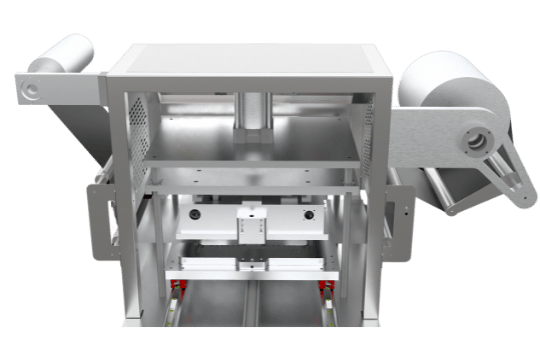

Advanced Gas Flushing

Extended Shelf-Life

IP65 Standards

Types of packages

Gas Flushing

Premium Sealing

Modified Atmospheric Packaging

Skin

Products that can be packed

Dates

Sweet

Namkeen & Farsan

Ready & Cooked Meals

Bakery

Meat & Poultry

Sea Food

Fruits and Vegetable

Technical Specification

Production Capacity |

||

|---|---|---|

| Production Capacity |

Upto 4 to 5 Cycles per Minute (Depend on Product) |

|

| Production Output |

960 to 1200 Trays per Hour (for 200 Grams or 250 Grams) |

|

| Products |

Meat, Sweets & Savories, Bakery |

|

Machine Specification |

||

| Type | Top Sealing | |

| Application | MAP, Sealing, Skin | |

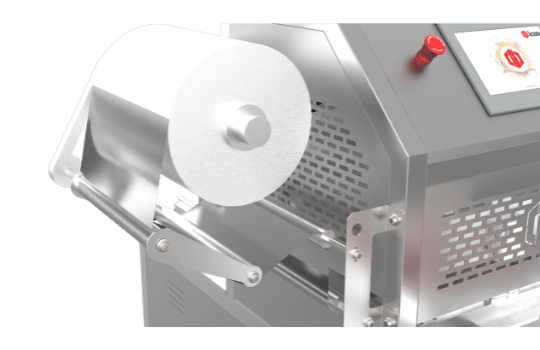

| Upper Film | Printed / Plain, Easy Peel, Retortable | |

| Tray Material | High Barrier Rigid (Pre-Formed) | |

| Tray Shape and Size | Customized | |

| Vacuum Pump | Busch / Becker | |

| Mold Matrix |

Depend on the Tray Size |

|

| Packet Weight Variants | 100, 200, 400, 500, and 1000 Grams, etc. (Can be customized) | |

| Feeding System | Manual Placement of the Tray in the Feeding Area | |

Electrical Specification |

||

|

Control & Command System |

PLC & HMI 7" (Touch Screen) (Fuji) |

|

|

Power Consumption |

8 KW |

|

| Power Supply | 440V AC (3-Phase) | |

Pneumatic Specification |

||

| Air Pressure | 6 to 7 Bar | |

| Pneumatic Components | SMC or Festo | |

Machine Structure |

||

| Machine Construction | Stainless Steel 304 & Aluminum Assemblies | |

|

Machine Length |

~ 1641 mm |

|

|

Machine Width |

~ 1294 mm |

|

|

Machine Height |

~ 1275 mm | |

| Machine Weight | ~ 250 Kg. | |

Required Accessories |

||

| Air Compressor | 3 H.P. | |

| Air Dryer | 20 CFM | |

| Printer | Inkjet Printer with Conveyor |

.png)

.png)

.png)

.png)

(24).png)